The Covid-19 pandemic has crippled the global supply chain systems causing Supply network disruptions for many organizations across the world.While Some organizations like the largest Milk co-operative of India successfully sustained the COVID Impact, Organizations across the globe are penning alternative Supply Chain and sourcing strategies to sustain future risks based on the foreseen scenarios.

Global Supply chain experts emphasising on building highly resilient supply chains with the focus on:

- Improved supply chain visibility

- Risk Mitigation and Cost Reduction

- The transition from Traditional to Digital Supply Networks

- Building a Resilient Supply chain

Improved supply chain visibility

According to a Survey by Dun & Bradstreet, At least 51,000 companies which include 163 of the Fortune 1000 around the world have one or more direct or Tier 1 suppliers in the Pandemic impacted regions of China, and at least five million companies which include 938 of the Fortune 1000 have one or more Tier 2 suppliers in the impacted regions of China.

With the traditional supply chains spread across the countries, it is very difficult to get the visibility over the Tier 2 and further tier Suppliers where the organizations usually do not have a direct connect.

To keep discontinuity at check especially with the high risk category suppliers: Packaging material suppliers and logistics partners, Organizations are adopting novel Risk assessment approaches. Digital transformation is Vital to gain visibility over Tier 2, and tertiary suppliers.

Risk Mitigation and Cost Reduction

Organizations are adopting tools and technologies that provide deep supply chain intelligence. Modern Technologies like AI and ML can predict future pandemics and other challenging trends patterns.

Global firms are reducing their variable costs and focusing on keeping the cash flows positive.

By aligning the internal IT to the flexible working models, companies are enabling Remote work and thus reducing the disruptions that are caused due to employee absenteeism.

Buying additional inventory as strategic safety stocks, enabling flexible payment options are some of the other practices to keep the costs under control.

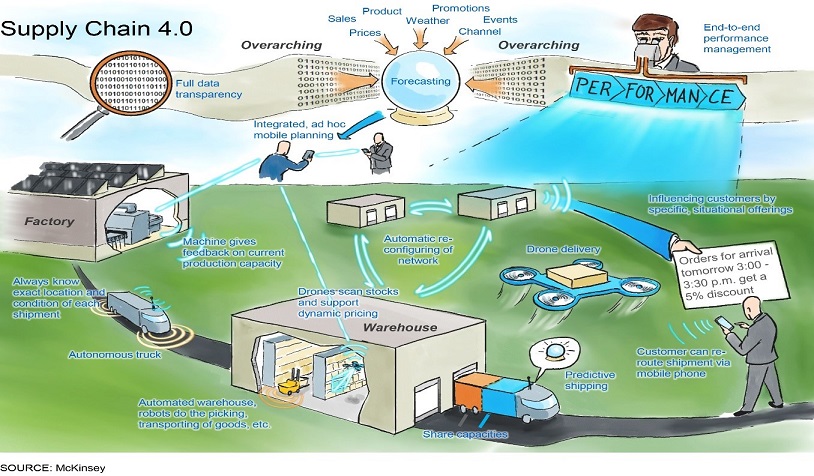

Transition from Traditional Supply chain to Digital Supply Network

Source:McKinsey

Today, Advanced technologies can help build a highly resilient supply chain less difficult. Technologies like Cloud computing, AI/ML, IoT, 5G and robotics can help build the future-ready digital supply

Companies are learning from the pandemic and being prepared for the force majeure events.

Building a Digital Supply Network eliminates the linearity of the supply chain induces dynamism thus establishes resilience.

Building Resilient Supply chain

The learnings from the pandemic are helping organizations to understand stand their supply chains better and reemphasising the focus to establish resilience.There is also an increasing trend of revisiting the Asia-Pacific operating models.

Improved engagements with end customers and suppliers using Digital mediums is another characteristic of a resilient supply chain. While it is difficult to define a common definition of risk for all the industries, the focus is on mitigating risks and building a resilient supply chain that withstands the supply disruptions.

Role of Sonata's Digital Platforms in building a Resilient Supply Chain

Sonata leverages the power of platforms to help clients create & implement platform-based business models.

Sonata’s Modern Distribution is a future ready digital supply chain platform with rich features and functionalities bringing together all elements to drive growth through new channels of engagement, ensuring channel loyalty and best in class margin management.

The platform enables digital commerce with customers & suppliers, optimizes overall supply chain performance and provides Digital engagements with Channel partners and end customers.

Visit our Distribution& Manufacturing offering page to explore the Digital platforms that help build a resilient supply chain.